Dry-Type Transformers

Custom Designed & Built Low- to Medium-Voltage Transformers

WR specializes in customized dry-type transformers. Each transformer is designed in-house to meet the customer’s specifications and manufactured for longer-lasting performance in harsh operating conditions.

Transformers from our ISO 9001:2015-certified US and Canadian manufacturing facilities are built to the same high-quality standards and North American certifications.

Building transformers to your specification is our specialty!

More than 9,000 custom-built WR Transformers are installed around the world!

Dry-Type Transformer Product Lines

Building to Your Specification is Our Specialty

AutoTransformer

An Autotransformer is a type of transformer that uses a single winding to step up and step down voltage. It consists of a single coil that has taps along its length, allowing the user to select the required voltage ratio. It is usually used in applications where the voltage needs to be adjusted by a small amount. Autotransformers are also often used in variable speed drives, voltage stabilization and other power conditioning applications.

Distribution Transformer

(General Application)

A Distribution Transformer is an electrical device that reduces the voltage of an electrical power system. This is usually done to lower the voltage of a power transmission line to a level that is suitable for everyday use by the public or commercial businesses. In comparison to power transformers, distribution transformers possess a lesser MVA rating and are employed in electrical networks with lower voltage.

Grounding Transformer

A Grounding Transformer is a transformer used to provide a source of zero-sequence current. This type of transformer is typically used in power distribution systems to provide an effective ground connection and protect against electrical hazards, such as fire and electrocution. Grounding transformers are also used to provide a neutral point of connection for the power supply system, which can help regulate voltage levels and protect against power surges.

Grounding Zig-Zag Transformer

A Grounding Zig-Zag Transformer is a style of grounding transformer used to provide a source of zero-sequence current. This type of transformer consists of two coils connected in a zig-zag configuration, which helps to reduce the potential of circulating currents and improve the system’s fault current capacity. Grounding zig-zag transformers are used in power distribution systems to provide an effective ground connection and protect against electrical hazards like fire and electrocution.

Non-Linear Loaded Transformer

A Non-Linear Loaded Transformer is a form of transformer created to transfer electrical energy from a source to a load, while shielding the source and load from harm caused by current and voltage spikes. These transformers are employed in applications where the load is non-linear, such as AC/DC rectifiers, DC/DC converters, and uninterruptible power supplies. Additionally, they can be used for power conditioning and offer supplementary current and voltage regulation.

Reactor-Type Transformer

A Reactor-Type Transformer is an inductor that controls voltage and limits short-circuit current in power systems. It consists of a wire coil that creates a magnetic field when current flows through it. The added inductive reactance has the effect of limiting the short-circuit current from the transformer. A series reactor sometimes limits current and voltage transients and provides short-circuit protection. Shunt reactors are used to increase the power and energy system efficiency as they absorb and compensate for the reactive power in cables and long high-voltage transmission lines.

Rectifier Transformer

A Rectifier Transformer is a type of transformer that is used to limit the magnitude of fault currents in a power system. This type of transformer consists of a primary winding and a secondary winding, both of which are connected in series with an inductive reactance. The inductive reactance helps to limit the fault current, thus preventing damage to the system components. Rectifier transformers are typically used in applications where the fault current must be limited to a low magnitude, such as in high-voltage transmission lines.

Variable-Speed Motor Transformer

This transformer for variable speed motors is designed to control the speed of an induction motor. It contains a set of windings connected in series and parallel to the motor, which allows the user to adjust the voltage and frequency of the motor. By varying the voltage and frequency of the motor, the speed of the motor can be controlled. This type of transformer is commonly used in applications such as conveyor systems and pumps, where variable-speed control is required.

Construction Features

Optional Features

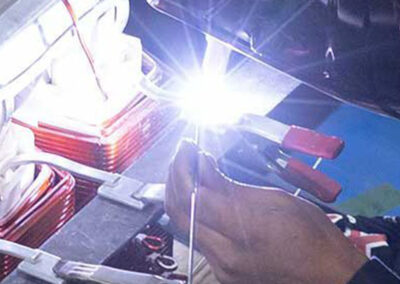

Windings

Copper or aluminum coils are vacuum-impregnated (VPI) with polyester resin, which seals out moisture from the windings and insulation and ensures reliable, longer lasting performance in harsh environments. The plug adjustments, located at the front, are easily accessible. Windings are made in layers or discs depending on the voltage level and the insulation class (BIL). For some applications, the strap can be used for winding low voltage, which minimizes eddy current losses and provides higher short circuit resistance.

Core

The core is a magnetic component made of laminated steel sheets that serves to transfer energy between the windings through magnetic flux. WR’s cores are constructed of high-quality grain-oriented steel with high magnetic permeability. Magnetic steel is prepared free of burrs and appropriately stacked. Magnetic flux density is kept below the saturation point, which minimizes core losses and reduces the sound level. The core is electrically insulated except for one point, where a copper strip connects the core to the yoke. The steel cutting is done with high precision, and then the core is vacuum impregnated with resin to help prevent corrosion. For larger capacity transformers and to avoid saturation, an air gap in the middle of the core uses electrical insulation so that air can freely circulate and cool it.

Core and Coil Assembly

The core and coil assembly in a dry-type transformer is the central functional unit where electrical energy is transferred between voltage levels using electromagnetic induction. The cores are compressed by high-density insulation blocks between the upper and lower frames to help withstand short-circuit forces. The transformers used in the mining sector are mechanically reinforced to handle being oriented at 90°. The standard connection type is “stub up,” utilizing NEMA-type holes with or without mechanical connectors. WR also offers the possibility of manufacturing and installing busbars to coordinate with low voltage (LV) and/or high voltage (HV) switches. This service is also available for adding Transition Chambers or an ATC Air Terminal Chamber. As an option, the addition of flexible braids eliminates vibration transmission from the transformer to the switching devices. They can be factory installed and ready for connection at the job site.

Mechanical Housing:

NEMA 1 or NEMA 3R

Mechanical housings used are either NEMA 1 or NEMA 3R type. These housings can have filters added to better protect the transformer from dust, water or snow. For greater strength and longevity, the enclosure can be manufactured with a range of thicknesses such as 11, 12 and 14 gauge. We also provide stainless steel enclosures for highly corrosive conditions, such as salt air. For mining operations, these transformers can be mounted on a stable metal base, making them easier to move and reducing the amount of work needed when connecting them to the control panel. For extremely harsh weather conditions, we offer a housing that has no ventilation.

Transition Chambers

To facilitate the electrical interface between high voltage (HV) and low voltage (LV) cables, a specially designed transition chamber can be incorporated to provide a protected space to connect incoming and outgoing cables. This space separates the HV and LV into compartments to help prevent electrical interference or faults, and ensures organized, safe and strain-relieved cable connections. To make sure the cables are securely installed, cable supports can be added.

Standard Characteristics of Our Electrical Dry-Type Transformers:

- From 15KVA to 30MVA

- Up to 49 KV

- Insulation class 220° C

- Temperature rise 150° C

- Frequency 60 Hz

- Efficiency according to C802.2-2018 or DOE 2016

- 4 bolted link adjustable taps (2 X 2.5% FCAN, FCBN)

- VPI treatment for core & coils

- Mechanical connection lugs included

- Nema 1 with lifting hook (Nema 3R also available)

These are the maximum temperature rise of our transformer windings. Data is based on an ambient temperature of 30°C, never to exceed 40°C.

Temperature (° C) | Average Winding Temperature Measured by Rise of Resistance (°C) | Winding (°C) |

| Class 105 | 55 | 65 |

| Class 130 | 75 | 90 |

| Class 150 | 90 | 110 |

| Class 180 | 115 | 140 |

| Class 200 | 130 | 160 |

| Class 220 | 150 | 180 |

TR Transformers are designed to reach SA C9 sound level. It is possible to reduce the sound level from 3 dB to 5 dB below standard.

| 5kV @ 15kV (95kV BIL @ 150kV BIL) | kVA |

| 60dB @ 62dB | 300 @ 500 |

| 62dB @ 64dB | >500 @ 750 |

| 64dB @ 66dB | >750 @ 1000 |

| 65dB @ 67dB | >1000 @ 15000 |

Tensions nominal kV | Standard kV (BIL) |

5.0 | 30 |

8.7 | 45 |

15 | 60 |

18 | 95 |

25 | 125 |

35 | 150 |

%

Customer Satisfaction Guaranteed

Contact Us

Privacy officer

Geneviève Hainault

genevieve.hainault@wrxfo.com (450) 994-4249 extention 103

US OFFICE

CANADA OFFICE

2961 Rue Brodeur E,

Saint-Alphonse-de-Granby, QC J0E 2A0

LOCAL: 450-994-4249

TOLL-FREE: 855-294-1559

9am-5pm ET Mon - Friday