About WR Transformers

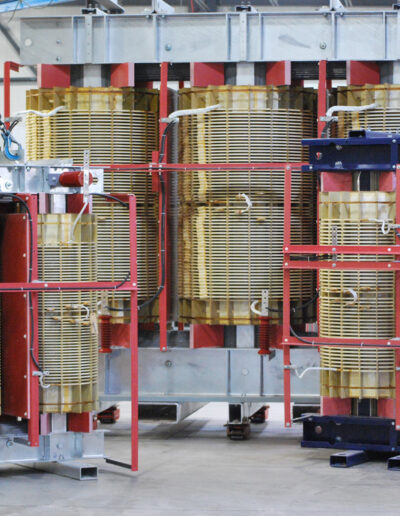

Since 2013, WR Transformers has been a top North American manufacturer of high-performance dry-type electrical transformers. With more than 7,000 units installed globally, our transformers support critical operations across a wide range of industries that depend on reliable power transformation systems.

Our advanced manufacturing facilities in the U.S. and Canada are ISO 9001:2015 certified and specialize in producing custom-engineered dry-type transformers tailored to exact customer specifications.

If you are interesting in working at WR, click here.

What Do WR Transformer Customers Experience?

High-Quality, Experienced Craftsmanship

At WR Transformers, quality begins with North American-sourced materials and ends with the on-time delivery of a customized, built-for-purpose dry-type transformer. We never use cheap imported parts or materials that can compromise transformer life or efficiency. Every transformer is built for long-term, reliable power delivery, even in harsh environments.

Custom Transformer Solutions

WR collaborates directly with design engineers and project managers to create transformers tailored to your unique operational or environmental needs. Whether you’re powering a mine, smelter, utility or hyperscale facility, we can deliver a solution that meets your exact specifications.

Every WR unit is designed for durability, thermal performance and electrical safety.

Transformers Built for Harsh Environments

Our dry-type transformers are engineered to operate in demanding industrial conditions, including:

- Underground and Surface Mining Operations

- Aluminum Smelters

- Oil Refineries & Gas Processing Facilities

- Power-Hungry Data Centers

- Remote Energy or Temporary Power Installations

Proven Service & Support

Since 2013, WR has worked hard to develope a reputation on-time delivery, personalized support and fast turnaround on custom orders.

From design to final testing, WR Transformers is your partner in dependable power.

High-Quality Dry-Type Transformers Produced by Experienced Craftsmen

Frequently Asked Questions (FAQ)

Is WR a top 10 power transformer manufacturer in the USA?

Yes. WR is one of the leading transformer manufacturers in the USA. With two facilities serving North America, WR has been providing dry-type transformers for industries in the United States since 2013. In fact, we have more than 7,000 dry-type transformers in service in North America and around the world.

Where does WR manufacture its dry-type transformers?

WR has two manufacturing facilities. Our original facility is located in south of Montreal in Saint-Alphonse-de-Granby, Québec. Our United States manufacturing facility is in Tomball, Texas, a suburb of Houston. Both facilities produce identical transformer product lines and have ISO/IEC 17025-certified testing labs.

Does WR have ISO 9001 certification?

Yes, both of our facilites – in the United States and Canada – are ISO 9001:2015 certified. See more about our facility and product certifications by clicking here.

Where are WR Transformers used?

WR transformers have been installed cross five continents and are used to support a wide range of industries including surface and underground mining data centers, pulp and paper, aluminum smelting and micro-networks. Other essential industries in which these transformers are used include hospitals, factories, schools, pharmacies, grocery stores and other applications requiring a secure and consistent, reliable energy.

What is VPI?

VPI stands for Vacuum Pressure Impregnation, a process used by WR Transformers to remove air and moisture from voids in the windings/coils. This is achieved by impregnating the windings /coil with varnish or resin under vaccuum and positive pressure. This process provides additional mechanical strength that can resist vibration and short-circuit forces and provide the end-user with longer service life and lower overall maintenance. Blocking moisture, dust and other environmental factors from the windings and coil also helps prevent premature deterioration of the transformer’s performance.

What is a dry-type electrical transformer?

A dry-type transformer is a type of electrical transformer that uses air instead of liquid (like oil) to cool its coils and core.

WR is one of the top transformer manufacturers of dry-type transformers, which play a crucial role in industrial operations due to their safety, efficiency and adaptability. Unlike oil-filled transformers, which use liquid coolant, dry-type transformers use air for cooling. Here’s why they’re particularly important in industrial environments:

Enhanced Safety

- No flammable liquids: Without oil or other flammable materials, dry-type transformers reduce fire risk significantly. This makes them suitable for environments where fire safety is a high priority, such as chemical plants or manufacturing facilities.

- Explosion resistance: There’s a much lower risk of catastrophic failure involving fire or explosions, which makes them ideal for indoor or densely populated industrial settings.

Minimal Maintenance

- Dry-type transformers have fewer moving or liquid parts, which reduces the likelihood of leaks and breakdowns.

- They are less prone to contamination and can be cleaned with minimal disruption to operations.

Environmental Friendliness

- Because they don’t use oil or toxic coolants, dry-type transformers are considered to be more eco-friendly and pose no risk of soil or groundwater contamination.

- They are often compliant with stringent environmental regulations, making them a good choice for green initiatives.

What is an electrical transformer?

An electrical transformer for industrial applications is used to transfer electrical energy between two or more circuits through electromagnetic induction and step down the incoming power line voltage to meet specific power requirements.

Contact Us

Privacy officer

Geneviève Hainault

genevieve.hainault@wrxfo.com (450) 994-4249 extention 103

US OFFICE

CANADA OFFICE

2961 Rue Brodeur E,

Saint-Alphonse-de-Granby, QC J0E 2A0

LOCAL: 450-994-4249

TOLL-FREE: 855-294-1559

9am-5pm ET Mon - Friday